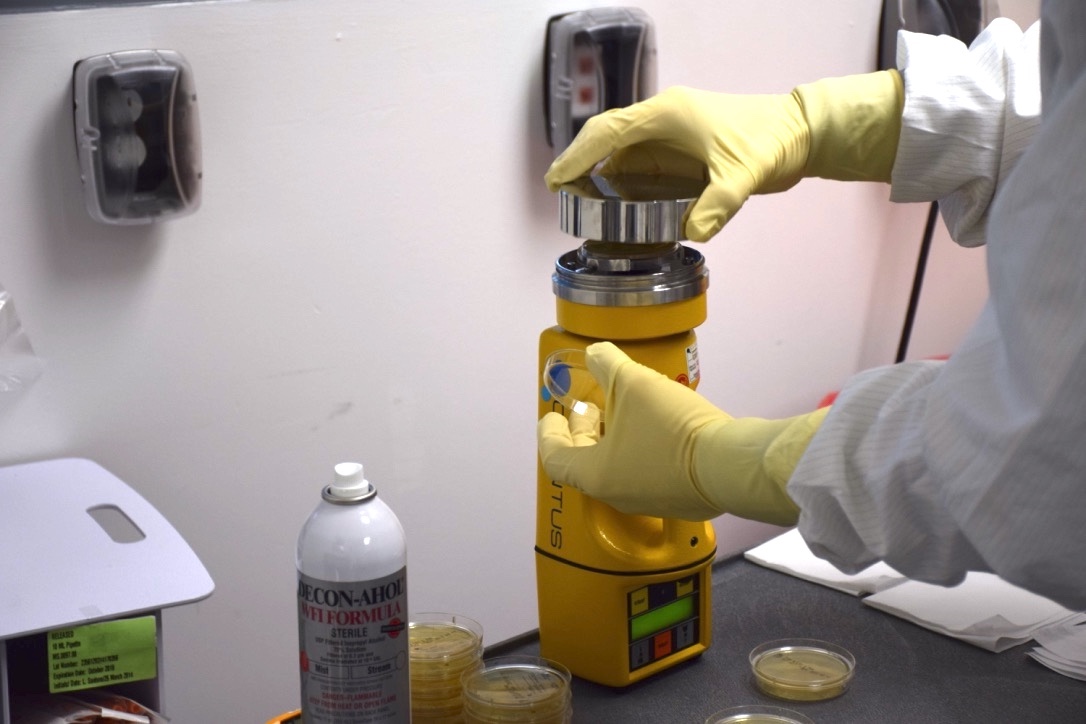

We calibrate a wide range of laboratory and manufacturing equipment crucial to Life Sciences R&D and production, including Autoclaves, Depyrogenation Ovens, Glass Washers, Water Systems, and various Building Monitoring Systems. Our services are designed to meet the rigorous standards set by FDA, EMA, USP, and other regulatory bodies.

Our approach focuses on efficient and strategic scheduling along with rapid onsite service execution. By performing calibrations onsite and tailoring our services to your operational schedule, we greatly reduce the downtime of your critical equipment, ensuring continuity in your highly regulated environment.

Absolutely. Our calibration processes are fully compliant with FDA, EMA, USP, and other regulatory standards. We employ NIST Traceable, ASTM, and ISO Compliant methods, ensuring that your equipment adheres to the strict guidelines required for Life Sciences operations.

We ensure transparency and prompt communication throughout our calibration process. For every service, we offer the flexibility to provide detailed calibration reports either on the same day or at the conclusion of the job, based on your preference and operational requirements. We understand the critical nature of out-of-tolerance (OOT) events for Life Sciences companies. Therefore, we work closely with you to document your specific requirements. Should you need immediate notification of OOT events, our technicians are instructed to alert you as soon as they are detected, in line with the directives outlined in their work orders. This ensures you're fully informed and can make necessary decisions without delay.

Our Asset & Data Management System (CMMS) is designed to handle multiple vendors and aggregate calibration data, allowing for centralized management of your entire facility's calibration needs. This streamlines the calibration process and provides you with a single point of contact for all your equipment maintenance scheduling and oversight.

- Learn More

Social icons

Social icons